Search results for: 'backing flange'

Products

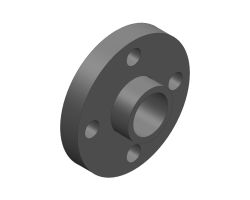

GEORG FISCHER

315 MM

GEORG FISCHER 315 MM

- For IR, butt and electrofusion welding according to DVS 2207

- Type A: without chamfer

- Type B: with chamfer

- Suitable for plastic butterfly valves type 567/578/565 up to DN250. ecoFit adapter SDR11 required for DN350 and above

- Suitable for metal butterfly valves type 038/039/044/065 up to DN250. ecoFit adapter SDR11 is required for DN350 and above

- Profile seal: d20-d800 NBR, EPDM, FKM

- Flat gasket: d20-d315 EPDM, FKM

- Pressure rating: 16 bar water / 10 bar gas

- Please refer to the Online Tool: Perfect Flange Connection - GF Piping Systems (gfps.com)

- FM 1613 approved - PN 15

- For IR, butt and electrofusion welding according to DVS 2207

- Type A: without chamfer

- Type B: with chamfer

- Suitable for plastic butterfly valves type 567/578/565 up to DN250. ecoFit adapter SDR11 required for DN350 and above

- Suitable for metal butterfly valves type 038/039/044/065 up to DN250. ecoFit adapter SDR11 is required for DN350 and above

- Profile seal: d20-d800 NBR, EPDM, FKM

- Flat gasket: d20-d315 EPDM, FKM

- Pressure rating: 16 bar water / 10 bar gas

- Please refer to the Online Tool: Perfect Flange Connection - GF Piping Systems (gfps.com)

- FM 1613 approved - PN 15

MILWAUKEE

STANDARD

MILWAUKEE STANDARD

- Cutting edge technology for maximum productivity.

- Tooth design - A 3.5 teeth per inch tooth design with a positive 10‚° tooth angle provides the following benefits: - Faster and more aggressive cut. - Improved heat dispersion during cutting ensures that the teeth stay sharper for longer. - Deeper curved gullets provide more efficient chip clearance preventing clogging and heat build up. - Special shaped tooth angle has less tendency to snag on thinner materials. - Teeth are altenate side set to minimise binding and friction. - Requires less feed pressure - This is achieved by the combination of aggressive tooth geometry and good chip clearance resulting in the requirement of less force during drilling.

- Tooth material - Type Matrix II premium high speed steel is used for the toothed area of the holesaw. Matrix II steel contains 8% cobalt allowing the teeth to retain the original tooth hardness even at high working temperatures when used in metal cutting applications. - Bi-Metal construction - High speed steel teeth are laser weldedonto a high alloy steel body. The teeth are then vacuum hardened to 65 HRC at a temperature of 600‚°C to give maximum durability and life time. - Due to the high wear resistance of the Matrix II material, these holesawsare ideal for cutting difficult and hard materials such as stainless steel and acid resistant steels as well as softer materials like wood.

- Holesaw body - 1.27 mm thick steel holesaw body is rigid to retain itsshape but also has built in elasticity. - Effective sawing depth is 41 mm.

- Back plate design - The back plates are constructed with thick steel thus the holes will not enlarge over time. Thick backs add strengthand rigidity minimising vibrations. - 4 drive pin holes for easier arbor location. - Perfectly manufactured round back plate, especially important for the larger diameter holesaws.

- Diagonal slots aid the removaland ejection of the core.

- Applications - High quality manufacturing techniques ensure high rotational precision, therefore these holesaws are suitable for use both in hand and pillar drills (manual feed only).L49224152

- Cutting edge technology for maximum productivity.

- Tooth design - A 3.5 teeth per inch tooth design with a positive 10‚° tooth angle provides the following benefits: - Faster and more aggressive cut. - Improved heat dispersion during cutting ensures that the teeth stay sharper for longer. - Deeper curved gullets provide more efficient chip clearance preventing clogging and heat build up. - Special shaped tooth angle has less tendency to snag on thinner materials. - Teeth are altenate side set to minimise binding and friction. - Requires less feed pressure - This is achieved by the combination of aggressive tooth geometry and good chip clearance resulting in the requirement of less force during drilling.

- Tooth material - Type Matrix II premium high speed steel is used for the toothed area of the holesaw. Matrix II steel contains 8% cobalt allowing the teeth to retain the original tooth hardness even at high working temperatures when used in metal cutting applications. - Bi-Metal construction - High speed steel teeth are laser weldedonto a high alloy steel body. The teeth are then vacuum hardened to 65 HRC at a temperature of 600‚°C to give maximum durability and life time. - Due to the high wear resistance of the Matrix II material, these holesawsare ideal for cutting difficult and hard materials such as stainless steel and acid resistant steels as well as softer materials like wood.

- Holesaw body - 1.27 mm thick steel holesaw body is rigid to retain itsshape but also has built in elasticity. - Effective sawing depth is 41 mm.

- Back plate design - The back plates are constructed with thick steel thus the holes will not enlarge over time. Thick backs add strengthand rigidity minimising vibrations. - 4 drive pin holes for easier arbor location. - Perfectly manufactured round back plate, especially important for the larger diameter holesaws.

- Diagonal slots aid the removaland ejection of the core.

- Applications - High quality manufacturing techniques ensure high rotational precision, therefore these holesaws are suitable for use both in hand and pillar drills (manual feed only).L49224152

GEORG FISCHER

10 IN

GEORG FISCHER 10 IN

- ANSI 150 Class according to ANSI B16.5

- 1/2" - 12" pressure rating is 150 psi @ 73°F (10.3 bar @ 22.7°C)

- 14" - 24" pressure rating is 100 psi @ 73°F (6.9 bar @ 22.7°C)- Steel Ring

- HC = Honeycomb (Face)

- ANSI 150 Class according to ANSI B16.5

- 1/2" - 12" pressure rating is 150 psi @ 73°F (10.3 bar @ 22.7°C)

- 14" - 24" pressure rating is 100 psi @ 73°F (6.9 bar @ 22.7°C)- Steel Ring

- HC = Honeycomb (Face)

MILWAUKEE

STANDARD

MILWAUKEE STANDARD

- Thunderweb design is characterised by a conical shaped web which gets thicker towards the back of the drill bit. Standard drill bits have a constant thickness throughout their length.Even at the narrowest point the Thunderweb core is thicker than that of a standard drill bit.

- Parabolic web cross section: Large web thickness. Strength built in.

- Flute geometry - Thunderweb flute form ejects hot chips rapidly. Dissipates heat better increasing life time.'

- 135‚° Split point - Precision starting, drill bit won't walk on material surface.Polished finish reduces friction and extends drill bit life.

- Impact resistant ABS case with added rubber corner protection.

- Accepts higher feed pressure and torque equalling less breakages.

- Thunderweb design is characterised by a conical shaped web which gets thicker towards the back of the drill bit. Standard drill bits have a constant thickness throughout their length.Even at the narrowest point the Thunderweb core is thicker than that of a standard drill bit.

- Parabolic web cross section: Large web thickness. Strength built in.

- Flute geometry - Thunderweb flute form ejects hot chips rapidly. Dissipates heat better increasing life time.'

- 135‚° Split point - Precision starting, drill bit won't walk on material surface.Polished finish reduces friction and extends drill bit life.

- Impact resistant ABS case with added rubber corner protection.

- Accepts higher feed pressure and torque equalling less breakages.

Grohe

STANDARD

Grohe STANDARD

- with mixture

- wall installation

- with adhesive flange for sealing the wall

- 2 stop valves

- non-return valve

- for use with 36 321 000

- with mixture

- wall installation

- with adhesive flange for sealing the wall

- 2 stop valves

- non-return valve

- for use with 36 321 000

Grohe

STANDARD

Grohe STANDARD

- adjustment ex factory 6 l and 3 l

- pneumatic discharge valve offering 3 modes of operation: dual flush or start/stop or single flush

- water supply from left/right/back or top

- low noise (group I acc. to German Noise Specification)

- insulated against condensation

- ½" water supply connection including integrated angle valve and push fit flexible hose union

- notools required for installation of inspection shaft

- for vertical or horizontal use

- flush pipe insulated against condensation

- fixing brackets

- for mounting of small flush plates revision shaft 40 911 000 needs to be ordered separately

- adjustment ex factory 6 l and 3 l

- pneumatic discharge valve offering 3 modes of operation: dual flush or start/stop or single flush

- water supply from left/right/back or top

- low noise (group I acc. to German Noise Specification)

- insulated against condensation

- ½" water supply connection including integrated angle valve and push fit flexible hose union

- notools required for installation of inspection shaft

- for vertical or horizontal use

- flush pipe insulated against condensation

- fixing brackets

- for mounting of small flush plates revision shaft 40 911 000 needs to be ordered separately

GEORG FISCHER

250 MM

GEORG FISCHER 250 MM

- For IR, butt and electrofusion welding according to DVS 2207

- Type A: without chamfer

- Type B: with chamfer

- Suitable for plastic butterfly valves type 567/578/565 up to DN250. ecoFit adapter SDR11 required for DN350 and above

- Suitable for metal butterfly valves type 038/039/044/065 up to DN250. ecoFit adapter SDR11 is required for DN350 and above

- Profile seal: d20-d800 NBR, EPDM, FKM

- Flat gasket: d20-d315 EPDM, FKM

- Pressure rating: 16 bar water / 10 bar gas

- Please refer to the Online Tool: Perfect Flange Connection - GF Piping Systems (gfps.com)

- FM 1613 approved - PN 15

- For IR, butt and electrofusion welding according to DVS 2207

- Type A: without chamfer

- Type B: with chamfer

- Suitable for plastic butterfly valves type 567/578/565 up to DN250. ecoFit adapter SDR11 required for DN350 and above

- Suitable for metal butterfly valves type 038/039/044/065 up to DN250. ecoFit adapter SDR11 is required for DN350 and above

- Profile seal: d20-d800 NBR, EPDM, FKM

- Flat gasket: d20-d315 EPDM, FKM

- Pressure rating: 16 bar water / 10 bar gas

- Please refer to the Online Tool: Perfect Flange Connection - GF Piping Systems (gfps.com)

- FM 1613 approved - PN 15

MILWAUKEE

STANDARD

MILWAUKEE STANDARD

- Fully compatible with SWITCH TANK™

- Chemical sprayer tank for pesticides/fertilizers/treatments/herbicides/fungicides/insecticides/de-icing agents and more

- Semi-transparent tank with measuring scale to know how much liquid is inside the tank

- Carry handle lid with wide mouth makes easy transport and pouring of water/chemicals into tank

- Comfortable rubber gripped spray wand handle with ability to lock-on for larger jobs

- Sprayer wand storage to save space and avoid damage during transport

- Integrated strainer prevents debris from entering the tank

- Adjustable spraypattern - from cone to straight stream for end user preference and application. Up to 7.6 m spray distance

- 5-mode pressure adjustment knob

- UV and chemical resistant

- When equipped with an M18™ REDLITHIUM™ 4.0 Ah battery it provides up to 12 tanks of spraying per charge

- Fully compatible with SWITCH TANK™

- Chemical sprayer tank for pesticides/fertilizers/treatments/herbicides/fungicides/insecticides/de-icing agents and more

- Semi-transparent tank with measuring scale to know how much liquid is inside the tank

- Carry handle lid with wide mouth makes easy transport and pouring of water/chemicals into tank

- Comfortable rubber gripped spray wand handle with ability to lock-on for larger jobs

- Sprayer wand storage to save space and avoid damage during transport

- Integrated strainer prevents debris from entering the tank

- Adjustable spraypattern - from cone to straight stream for end user preference and application. Up to 7.6 m spray distance

- 5-mode pressure adjustment knob

- UV and chemical resistant

- When equipped with an M18™ REDLITHIUM™ 4.0 Ah battery it provides up to 12 tanks of spraying per charge

MILWAUKEE

STANDARD

MILWAUKEE STANDARD

- Brushless POWERSTATE™ motor delivers fast cutting speed through common materials without slowing or bogging down in hardwoods

- Adjustable 10,000 to 20,000 opm allow the user toget the perfect cut whatever the material

- Lowest vibration in its class, 4.56 m/s‚² driving productivity through performance and safety

- 1.8‚° left/right oscillation angle allowing faster cuts

- Ability to make up to 59 cuts in oak on one 2.0 Ah battery charge

- REDLINK PLUS™ intelligence system delivers an advanced digital overload protection for tool and battery and uniquely enhances the tool performance under load

- FIXTEC™ tool free blade change with universal blade change adaptor included to accept all major competitor blades

- LED work light illuminates the cut line in low light conditions

- Suppliedwith an adapter, plunge cut blade OSC 112, sanding backing pad, 5 x sanding sheets and a DEK26 dust guard to use when sanding

- REDLITHIUM™ battery pack provides superior pack construction, electronics and fade-free performance to deliver more run time and more work over pack life

- Flexible battery system: works with all MILWAUKEE‚® M12™ batteries

- Brushless POWERSTATE™ motor delivers fast cutting speed through common materials without slowing or bogging down in hardwoods

- Adjustable 10,000 to 20,000 opm allow the user toget the perfect cut whatever the material

- Lowest vibration in its class, 4.56 m/s‚² driving productivity through performance and safety

- 1.8‚° left/right oscillation angle allowing faster cuts

- Ability to make up to 59 cuts in oak on one 2.0 Ah battery charge

- REDLINK PLUS™ intelligence system delivers an advanced digital overload protection for tool and battery and uniquely enhances the tool performance under load

- FIXTEC™ tool free blade change with universal blade change adaptor included to accept all major competitor blades

- LED work light illuminates the cut line in low light conditions

- Suppliedwith an adapter, plunge cut blade OSC 112, sanding backing pad, 5 x sanding sheets and a DEK26 dust guard to use when sanding

- REDLITHIUM™ battery pack provides superior pack construction, electronics and fade-free performance to deliver more run time and more work over pack life

- Flexible battery system: works with all MILWAUKEE‚® M12™ batteries

![MILWAUKEE M12 MULTI-TOOL [BARE-TOOL] | M12FMT-0](https://catalyst-dev2.wylog.com/media/catalog/product/cache/503f2f5e25f27962b01fad949171e229/M/I/MIL4933472238_0_7.jpg?t=20260210)

WhatsApp us!

WhatsApp us!