Search results for: 'non pressure testing'

Products

GEORG FISCHER

20 MM

GEORG FISCHER 20 MM

- Material: PVC-C, heat resistant

- Dimension: acc. to DIN 8079/80

- Colour: agate grey RAL 7038

- Pipe length: 5000mm, with plain ends

- Note 1: DVGW certification

- Attention: Pressure rates refer to operating temperatures at 20°C. Higher temperatures and aggressive flow media reduce pressure load (see above DIN and our technical documentation). Pressure load capacity has to be determined in consideration with safety demands of the respective applications and calculated in accordance.

- Material: PVC-C, heat resistant

- Dimension: acc. to DIN 8079/80

- Colour: agate grey RAL 7038

- Pipe length: 5000mm, with plain ends

- Note 1: DVGW certification

- Attention: Pressure rates refer to operating temperatures at 20°C. Higher temperatures and aggressive flow media reduce pressure load (see above DIN and our technical documentation). Pressure load capacity has to be determined in consideration with safety demands of the respective applications and calculated in accordance.

GEORG FISCHER

25 MM

GEORG FISCHER 25 MM

- Material: PVC-C, heat resistant

- Dimension: acc. to DIN 8079/80

- Colour: agate grey RAL 7038

- Pipe length: 5000mm, with plain ends

- Note 1: DVGW certification

- Attention: Pressure rates refer to operating temperatures at 20°C. Higher temperatures and aggressive flow media reduce pressure load (see above DIN and our technical documentation). Pressure load capacity has to be determined in consideration with safety demands of the respective applications and calculated in accordance.

- Material: PVC-C, heat resistant

- Dimension: acc. to DIN 8079/80

- Colour: agate grey RAL 7038

- Pipe length: 5000mm, with plain ends

- Note 1: DVGW certification

- Attention: Pressure rates refer to operating temperatures at 20°C. Higher temperatures and aggressive flow media reduce pressure load (see above DIN and our technical documentation). Pressure load capacity has to be determined in consideration with safety demands of the respective applications and calculated in accordance.

GEORG FISCHER

63 MM

GEORG FISCHER 63 MM

- 10 bar Gas / 16 bar Water

- d160 up to d225 are supplied with base plate and straps

- d1 = diameter of bore

- Regarding pressure rate and application local standardsand regulations have to be considered

- 10 bar Gas / 16 bar Water

- d160 up to d225 are supplied with base plate and straps

- d1 = diameter of bore

- Regarding pressure rate and application local standardsand regulations have to be considered

GEORG FISCHER

STANDARD

GEORG FISCHER STANDARD

- 10 bar Gas / 16 bar Water

- Branch Saddle installation only with installation set Topload TL225 (799.300.807)

- Angle adaptors (799.350.340) for fusion cable required

- 4 mm pin connectors

- Limited path fusion indicators

- Spigot outlet for butt- and electrofusion

- Full pressure applicable - no derating factor

- With integrated pressure test port for test cap (799.199.287)

- 10 bar Gas / 16 bar Water

- Branch Saddle installation only with installation set Topload TL225 (799.300.807)

- Angle adaptors (799.350.340) for fusion cable required

- 4 mm pin connectors

- Limited path fusion indicators

- Spigot outlet for butt- and electrofusion

- Full pressure applicable - no derating factor

- With integrated pressure test port for test cap (799.199.287)

GEORG FISCHER

160 MM

GEORG FISCHER 160 MM

- 10 bar Gas / 16 bar Water

- With integrated drill bit to tap live mains under pressure

- Complete with lower part and premounted PE100 coated valve piece

- The valveis closed clockwise

- Number of turns to fully open or close valve is 13 for outlet d32

- Number of turns to fully open or close valve is 28 for outlet d63

- Spindle size (SW) 14

- 4 mm pin connectors

- Limited path fusion indicators

- Long fusion outlet

- 10 bar Gas / 16 bar Water

- With integrated drill bit to tap live mains under pressure

- Complete with lower part and premounted PE100 coated valve piece

- The valveis closed clockwise

- Number of turns to fully open or close valve is 13 for outlet d32

- Number of turns to fully open or close valve is 28 for outlet d63

- Spindle size (SW) 14

- 4 mm pin connectors

- Limited path fusion indicators

- Long fusion outlet

MILWAUKEE

STANDARD

MILWAUKEE STANDARD

- Step drills are ideal for drilling into the following materials: - Ferrous & non-ferrous sheets metals, profiles and pipes. - Copper, brass and aluminium. - Stainless steel. - Plastics. - Maximum material thickness 4 mm. - To ensure best lifetime we recommend the use of a coolant.

- Trades: - Electrical: drilling of panels and cabinets for cable gland installation. - Plumbing / HVAC: access holes for pipework and installation. - Metal workers / fabrication: various sizes and hole enlargement. - Automotive: holes for cable installation (mobile telephones, antennas, re-directing electrical wiring). - Maintenancerepair operations: various applications, sizes and hole enlargement.

- Step Drill advantages over conventional drill bits: - One drill bit to drill multiple sizes - Do more carry less! - Best option for enlargingexisting holes. - More durable than twist drill bits, thick core resists breakage. - More accurate and less walking, tip starts on contact. - Clean burr free holes, less reaming required. - Drills plastic without splitting or cracking.

- MILWAUKEE‚® Advantages

- Spot drill - Drill - Deburr - All in one go

- RAPID STRIKE TIP™: Accurate start without walking and fast drilling without the need to pre-drill the material.

- Special tip and step geometry for jam-free performance - less risk of drill snagging when used with high speed cordless tools and also prevents deformation of the drilled material.

- Optimised 2 flute groundsharpened edge geometry for 2 x faster and smoother cutting.

- Produced from custom engineered steel with black oxide coating for 4 x longer life.

- Optimised for use with high speed cordless drills.

- Laser engraved size markings for best long term visibility.

- Each step is relief ground to drill and deburr automatically.

- With 3 flat secure grip to prevent step drill from slipping in the chuck and ensure maximum transmission of torque.

- Step drills are ideal for drilling into the following materials: - Ferrous & non-ferrous sheets metals, profiles and pipes. - Copper, brass and aluminium. - Stainless steel. - Plastics. - Maximum material thickness 4 mm. - To ensure best lifetime we recommend the use of a coolant.

- Trades: - Electrical: drilling of panels and cabinets for cable gland installation. - Plumbing / HVAC: access holes for pipework and installation. - Metal workers / fabrication: various sizes and hole enlargement. - Automotive: holes for cable installation (mobile telephones, antennas, re-directing electrical wiring). - Maintenancerepair operations: various applications, sizes and hole enlargement.

- Step Drill advantages over conventional drill bits: - One drill bit to drill multiple sizes - Do more carry less! - Best option for enlargingexisting holes. - More durable than twist drill bits, thick core resists breakage. - More accurate and less walking, tip starts on contact. - Clean burr free holes, less reaming required. - Drills plastic without splitting or cracking.

- MILWAUKEE‚® Advantages

- Spot drill - Drill - Deburr - All in one go

- RAPID STRIKE TIP™: Accurate start without walking and fast drilling without the need to pre-drill the material.

- Special tip and step geometry for jam-free performance - less risk of drill snagging when used with high speed cordless tools and also prevents deformation of the drilled material.

- Optimised 2 flute groundsharpened edge geometry for 2 x faster and smoother cutting.

- Produced from custom engineered steel with black oxide coating for 4 x longer life.

- Optimised for use with high speed cordless drills.

- Laser engraved size markings for best long term visibility.

- Each step is relief ground to drill and deburr automatically.

- With 3 flat secure grip to prevent step drill from slipping in the chuck and ensure maximum transmission of torque.

GEORG FISCHER

110 x 90 MM

GEORG FISCHER 110 x 90 MM

- Pressure rating: 10 bar water / 5 bar gas

- Pressure rating: 10 bar water / 5 bar gas

MILWAUKEE

STANDARD

MILWAUKEE STANDARD

- Cutting edge technology for maximum productivity.

- Tooth design - A 3.5 teeth per inch tooth design with a positive 10‚° tooth angle provides the following benefits: - Faster and more aggressive cut. - Improved heat dispersion during cutting ensures that the teeth stay sharper for longer. - Deeper curved gullets provide more efficient chip clearance preventing clogging and heat build up. - Special shaped tooth angle has less tendency to snag on thinner materials. - Teeth are altenate side set to minimise binding and friction. - Requires less feed pressure - This is achieved by the combination of aggressive tooth geometry and good chip clearance resulting in the requirement of less force during drilling.

- Tooth material - Type Matrix II premium high speed steel is used for the toothed area of the holesaw. Matrix II steel contains 8% cobalt allowing the teeth to retain the original tooth hardness even at high working temperatures when used in metal cutting applications. - Bi-Metal construction - High speed steel teeth are laser weldedonto a high alloy steel body. The teeth are then vacuum hardened to 65 HRC at a temperature of 600‚°C to give maximum durability and life time. - Due to the high wear resistance of the Matrix II material, these holesawsare ideal for cutting difficult and hard materials such as stainless steel and acid resistant steels as well as softer materials like wood.

- Holesaw body - 1.27 mm thick steel holesaw body is rigid to retain itsshape but also has built in elasticity. - Effective sawing depth is 41 mm.

- Back plate design - The back plates are constructed with thick steel thus the holes will not enlarge over time. Thick backs add strengthand rigidity minimising vibrations. - 4 drive pin holes for easier arbor location. - Perfectly manufactured round back plate, especially important for the larger diameter holesaws.

- Diagonal slots aid the removaland ejection of the core.

- Applications - High quality manufacturing techniques ensure high rotational precision, therefore these holesaws are suitable for use both in hand and pillar drills (manual feed only).L49224152

- Cutting edge technology for maximum productivity.

- Tooth design - A 3.5 teeth per inch tooth design with a positive 10‚° tooth angle provides the following benefits: - Faster and more aggressive cut. - Improved heat dispersion during cutting ensures that the teeth stay sharper for longer. - Deeper curved gullets provide more efficient chip clearance preventing clogging and heat build up. - Special shaped tooth angle has less tendency to snag on thinner materials. - Teeth are altenate side set to minimise binding and friction. - Requires less feed pressure - This is achieved by the combination of aggressive tooth geometry and good chip clearance resulting in the requirement of less force during drilling.

- Tooth material - Type Matrix II premium high speed steel is used for the toothed area of the holesaw. Matrix II steel contains 8% cobalt allowing the teeth to retain the original tooth hardness even at high working temperatures when used in metal cutting applications. - Bi-Metal construction - High speed steel teeth are laser weldedonto a high alloy steel body. The teeth are then vacuum hardened to 65 HRC at a temperature of 600‚°C to give maximum durability and life time. - Due to the high wear resistance of the Matrix II material, these holesawsare ideal for cutting difficult and hard materials such as stainless steel and acid resistant steels as well as softer materials like wood.

- Holesaw body - 1.27 mm thick steel holesaw body is rigid to retain itsshape but also has built in elasticity. - Effective sawing depth is 41 mm.

- Back plate design - The back plates are constructed with thick steel thus the holes will not enlarge over time. Thick backs add strengthand rigidity minimising vibrations. - 4 drive pin holes for easier arbor location. - Perfectly manufactured round back plate, especially important for the larger diameter holesaws.

- Diagonal slots aid the removaland ejection of the core.

- Applications - High quality manufacturing techniques ensure high rotational precision, therefore these holesaws are suitable for use both in hand and pillar drills (manual feed only).L49224152

GEORG FISCHER

125 MM

GEORG FISCHER 125 MM

- Packed in cardboard boxes / PN 16

- Mono-layer pipe

- Material: PB

- SDR: 11

- Operation pressure: 16 bars

- Packed in cardboard boxes / PN 16

- Mono-layer pipe

- Material: PB

- SDR: 11

- Operation pressure: 16 bars

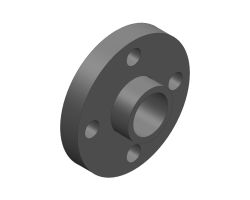

GEORG FISCHER

10 IN

GEORG FISCHER 10 IN

- ANSI 150 Class according to ANSI B16.5

- 1/2" - 12" pressure rating is 150 psi @ 73°F (10.3 bar @ 22.7°C)

- 14" - 24" pressure rating is 100 psi @ 73°F (6.9 bar @ 22.7°C)- Steel Ring

- HC = Honeycomb (Face)

- ANSI 150 Class according to ANSI B16.5

- 1/2" - 12" pressure rating is 150 psi @ 73°F (10.3 bar @ 22.7°C)

- 14" - 24" pressure rating is 100 psi @ 73°F (6.9 bar @ 22.7°C)- Steel Ring

- HC = Honeycomb (Face)

MILWAUKEE

STANDARD

MILWAUKEE STANDARD

- Thunderweb design is characterised by a conical shaped web which gets thicker towards the back of the drill bit. Standard drill bits have a constant thickness throughout their length.Even at the narrowest point the Thunderweb core is thicker than that of a standard drill bit.

- Parabolic web cross section: Large web thickness. Strength built in.

- Flute geometry - Thunderweb flute form ejects hot chips rapidly. Dissipates heat better increasing life time.'

- 135‚° Split point - Precision starting, drill bit won't walk on material surface.Polished finish reduces friction and extends drill bit life.

- Impact resistant ABS case with added rubber corner protection.

- Accepts higher feed pressure and torque equalling less breakages.

- Thunderweb design is characterised by a conical shaped web which gets thicker towards the back of the drill bit. Standard drill bits have a constant thickness throughout their length.Even at the narrowest point the Thunderweb core is thicker than that of a standard drill bit.

- Parabolic web cross section: Large web thickness. Strength built in.

- Flute geometry - Thunderweb flute form ejects hot chips rapidly. Dissipates heat better increasing life time.'

- 135‚° Split point - Precision starting, drill bit won't walk on material surface.Polished finish reduces friction and extends drill bit life.

- Impact resistant ABS case with added rubber corner protection.

- Accepts higher feed pressure and torque equalling less breakages.

GEORG FISCHER

STANDARD

GEORG FISCHER STANDARD

- Suitable for all kinds of pipe material. For use on plastic pipes please consult Georg Fischer Waga N.V.

- Single band clamp with full circle gasket

- All metal parts arestainless steel, quality AISI 304 (on request AISI 316)

- The rubber gasket is available in NBR (EPDM on request)

- Water and gas: NBR according to EN 682 (-10°C up to +70°C); potable water: EPDM according toEN 681-1 (-10°C up to +55°C)

- For working pressures in GAS please consult Georg Fischer Waga N.V.

- To choose the correct length of Multi/Clamp check our technical information

- Suitable for all kinds of pipe material. For use on plastic pipes please consult Georg Fischer Waga N.V.

- Single band clamp with full circle gasket

- All metal parts arestainless steel, quality AISI 304 (on request AISI 316)

- The rubber gasket is available in NBR (EPDM on request)

- Water and gas: NBR according to EN 682 (-10°C up to +70°C); potable water: EPDM according toEN 681-1 (-10°C up to +55°C)

- For working pressures in GAS please consult Georg Fischer Waga N.V.

- To choose the correct length of Multi/Clamp check our technical information

WhatsApp us!

WhatsApp us!