Search results for: 'accessories-wall plate'

Products

MILWAUKEE

230 MM

MILWAUKEE 230 MM

- Up to 50x longer life than standard Bi-Metal blades. Carbide teeth deliver long life and extreme durability in the toughest applications. Cuts through harderned screws and fastners.

- Up to 2x faster than standard Bi-Metal blades. A fast and aggressive 5 Tpi tooth pattern allows for the fastest cutting in nail embedded wood and a wide range of construction materials (wood/nails/bolts/screws/cast iron/asphalt roofing felt shingles).

- Up to 25% more cuts per charge vs. standard Bi-Metal blades. Optimised for use with cordless reciprocating saws.

- FANG TIP™: For faster plunge cutting and reaching into restricted areas.

- NAIL GUARD™: Protects the tooth during nail impacts for increased durability and lifetime.

- Sloped shape: Excellent for plunge cutting and reaching into restricted areas.

- Thick1.27 mm robust blade body for precise straight cuts.

- 25 mm blade height for improved stability and minimum vibration.

- Best for wood / nails / hardened fastners demolition

- Up to 50x longer life than standard Bi-Metal blades. Carbide teeth deliver long life and extreme durability in the toughest applications. Cuts through harderned screws and fastners.

- Up to 2x faster than standard Bi-Metal blades. A fast and aggressive 5 Tpi tooth pattern allows for the fastest cutting in nail embedded wood and a wide range of construction materials (wood/nails/bolts/screws/cast iron/asphalt roofing felt shingles).

- Up to 25% more cuts per charge vs. standard Bi-Metal blades. Optimised for use with cordless reciprocating saws.

- FANG TIP™: For faster plunge cutting and reaching into restricted areas.

- NAIL GUARD™: Protects the tooth during nail impacts for increased durability and lifetime.

- Sloped shape: Excellent for plunge cutting and reaching into restricted areas.

- Thick1.27 mm robust blade body for precise straight cuts.

- 25 mm blade height for improved stability and minimum vibration.

- Best for wood / nails / hardened fastners demolition

MILWAUKEE

150 MM

MILWAUKEE 150 MM

- Strong: Robust 1.06 mm thick body.

- Shatter resistant: The bi-metal blade body will bend and flex but not break.

- Torch: - Thick 1.06 mm robust blade body for precise cuts in sheet metal and pipes.

- 25 mm blade height for improved stability and minimum vibration.

- Strong: Robust 1.06 mm thick body.

- Shatter resistant: The bi-metal blade body will bend and flex but not break.

- Torch: - Thick 1.06 mm robust blade body for precise cuts in sheet metal and pipes.

- 25 mm blade height for improved stability and minimum vibration.

MILWAUKEE

STANDARD

MILWAUKEE STANDARD

- Especially engineered blades for exclusive use on 12 V HACKZALL™.

- Bi-Metal construction for increased tooth durability.

- Optimised tooth form for aggressive and fastercutting.

- Thinner blade body for better speed of cut and up to 35% more cuts per charge vs. standard Bi Metal blades.

- 75 mm scraper: for removing strong adhesive silicon, caulk, paint and rust.

- 125mm wide scraper: for removing glue, silicon, caulk, vinyl, rust, paint and wallpaper.

- Grout removal blade: for removing damaged or moulded grout between tiles.

- Especially engineered blades for exclusive use on 12 V HACKZALL™.

- Bi-Metal construction for increased tooth durability.

- Optimised tooth form for aggressive and fastercutting.

- Thinner blade body for better speed of cut and up to 35% more cuts per charge vs. standard Bi Metal blades.

- 75 mm scraper: for removing strong adhesive silicon, caulk, paint and rust.

- 125mm wide scraper: for removing glue, silicon, caulk, vinyl, rust, paint and wallpaper.

- Grout removal blade: for removing damaged or moulded grout between tiles.

MILWAUKEE

STANDARD

MILWAUKEE STANDARD

- Cutting edge technology for maximum productivity.

- Tooth design - A 3.5 teeth per inch tooth design with a positive 10‚° tooth angle provides the following benefits: - Faster and more aggressive cut. - Improved heat dispersion during cutting ensures that the teeth stay sharper for longer. - Deeper curved gullets provide more efficient chip clearance preventing clogging and heat build up. - Special shaped tooth angle has less tendency to snag on thinner materials. - Teeth are altenate side set to minimise binding and friction. - Requires less feed pressure - This is achieved by the combination of aggressive tooth geometry and good chip clearance resulting in the requirement of less force during drilling.

- Tooth material - Type Matrix II premium high speed steel is used for the toothed area of the holesaw. Matrix II steel contains 8% cobalt allowing the teeth to retain the original tooth hardness even at high working temperatures when used in metal cutting applications. - Bi-Metal construction - High speed steel teeth are laser weldedonto a high alloy steel body. The teeth are then vacuum hardened to 65 HRC at a temperature of 600‚°C to give maximum durability and life time. - Due to the high wear resistance of the Matrix II material, these holesawsare ideal for cutting difficult and hard materials such as stainless steel and acid resistant steels as well as softer materials like wood.

- Holesaw body - 1.27 mm thick steel holesaw body is rigid to retain itsshape but also has built in elasticity. - Effective sawing depth is 41 mm.

- Back plate design - The back plates are constructed with thick steel thus the holes will not enlarge over time. Thick backs add strengthand rigidity minimising vibrations. - 4 drive pin holes for easier arbor location. - Perfectly manufactured round back plate, especially important for the larger diameter holesaws.

- Diagonal slots aid the removaland ejection of the core.

- Applications - High quality manufacturing techniques ensure high rotational precision, therefore these holesaws are suitable for use both in hand and pillar drills (manual feed only).L49224152

- Cutting edge technology for maximum productivity.

- Tooth design - A 3.5 teeth per inch tooth design with a positive 10‚° tooth angle provides the following benefits: - Faster and more aggressive cut. - Improved heat dispersion during cutting ensures that the teeth stay sharper for longer. - Deeper curved gullets provide more efficient chip clearance preventing clogging and heat build up. - Special shaped tooth angle has less tendency to snag on thinner materials. - Teeth are altenate side set to minimise binding and friction. - Requires less feed pressure - This is achieved by the combination of aggressive tooth geometry and good chip clearance resulting in the requirement of less force during drilling.

- Tooth material - Type Matrix II premium high speed steel is used for the toothed area of the holesaw. Matrix II steel contains 8% cobalt allowing the teeth to retain the original tooth hardness even at high working temperatures when used in metal cutting applications. - Bi-Metal construction - High speed steel teeth are laser weldedonto a high alloy steel body. The teeth are then vacuum hardened to 65 HRC at a temperature of 600‚°C to give maximum durability and life time. - Due to the high wear resistance of the Matrix II material, these holesawsare ideal for cutting difficult and hard materials such as stainless steel and acid resistant steels as well as softer materials like wood.

- Holesaw body - 1.27 mm thick steel holesaw body is rigid to retain itsshape but also has built in elasticity. - Effective sawing depth is 41 mm.

- Back plate design - The back plates are constructed with thick steel thus the holes will not enlarge over time. Thick backs add strengthand rigidity minimising vibrations. - 4 drive pin holes for easier arbor location. - Perfectly manufactured round back plate, especially important for the larger diameter holesaws.

- Diagonal slots aid the removaland ejection of the core.

- Applications - High quality manufacturing techniques ensure high rotational precision, therefore these holesaws are suitable for use both in hand and pillar drills (manual feed only).L49224152

MILWAUKEE

STANDARD

MILWAUKEE STANDARD

- Suitable for applications in wood and metal.

- Suitable for applications in wood and metal.

MILWAUKEE

STANDARD

MILWAUKEE STANDARD

- NF C 20-130 for copper compression cable lugs

- NF C 20-130 for copper compression cable lugs

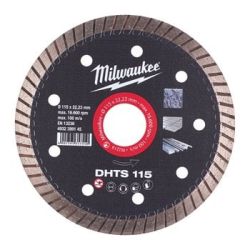

MILWAUKEE

STANDARD

MILWAUKEE STANDARD

- A trade quality turbo blade with extra thin body for very fast, precise and chip free cuts in thin materials such as granite, marble slabs and tiles (type: porcelain, gres, ceramic).

- Due to the high quality of this blade it is also suitable for cutting most building materials.

- A trade quality turbo blade with extra thin body for very fast, precise and chip free cuts in thin materials such as granite, marble slabs and tiles (type: porcelain, gres, ceramic).

- Due to the high quality of this blade it is also suitable for cutting most building materials.

MILWAUKEE

STANDARD

MILWAUKEE STANDARD

- Replacement saw chain to fit M18 FCHS chainsaw.

- Replacement saw chain to fit M18 FCHS chainsaw.

MILWAUKEE

190 MM

MILWAUKEE 190 MM

- Brushless POWERSTATE™ motor for up to 2x longer motor life and up to 25% more power

- REDLINK PLUS™ intelligence system delivers an advanced digital overload protection for tooland battery and uniquely enhances the tool performance under load

- REDLITHIUM™ battery pack provides superior pack construction, electronics and fade-free performance to deliver more run time and more work over pack life

- 190 mm blade delivers accurate cut capacities

- Quick release bevel setting allows the simple setting of bevel angles to the left and right

- Large sliding fences gives maximum support to thematerial being cut providing stability and accuracy

- Up to 299 cuts in 38 mm 89 mm soft wood with a 5.0 Ah battery gives the ability to work a full day without recharging the battery

- Light weight and portable at only 12.7 kg

- Integrated carry handle allows easy transportation on and off the jobsite

- Steel detent plate with preset angles gives repeatable accurate cuts

- LED light to illuminate the workpiece and cut line in low light conditions

- Flexible battery system: works with all MILWAUKEE‚® M18™ batteries

- Brushless POWERSTATE™ motor for up to 2x longer motor life and up to 25% more power

- REDLINK PLUS™ intelligence system delivers an advanced digital overload protection for tooland battery and uniquely enhances the tool performance under load

- REDLITHIUM™ battery pack provides superior pack construction, electronics and fade-free performance to deliver more run time and more work over pack life

- 190 mm blade delivers accurate cut capacities

- Quick release bevel setting allows the simple setting of bevel angles to the left and right

- Large sliding fences gives maximum support to thematerial being cut providing stability and accuracy

- Up to 299 cuts in 38 mm 89 mm soft wood with a 5.0 Ah battery gives the ability to work a full day without recharging the battery

- Light weight and portable at only 12.7 kg

- Integrated carry handle allows easy transportation on and off the jobsite

- Steel detent plate with preset angles gives repeatable accurate cuts

- LED light to illuminate the workpiece and cut line in low light conditions

- Flexible battery system: works with all MILWAUKEE‚® M18™ batteries

MILWAUKEE

305 MM

MILWAUKEE 305 MM

- Delivers the power to cut at the same rate of an equivalent AC 305mm saw, with the ability to cut up to 500 pieces of 78mm pine base board on one 12.0 Ah battery charge

- The HIGH OUTPUT™ system of tools elevates the M18 FUEL™ technologies to a new level and delivers extended performance and extended run time. These tools are designed to maximise the partnership with HIGH OUTPUT™ batteries

- Large sliding fences gives maximum support to the material being cut providing stability and accuracy

- Trenching stop with depth adjustment allows the user to make trenching and rebate cuts

- ONE-KEY™ tool tracking & security offers a free of charge cloud-based tracking network and inventory management platform for your tools. ONE-KEY™ also features a remote locking functionality

- Integrated carry handle allows easy transportation on and off the jobsite

- Steel detent plate with preset angles gives repeatable accurate cuts

- LED light to illuminate the work piece and cut line in low light conditions

- Flexiblebattery system: works with all MILWAUKEE‚® M18™ batteries

- Delivers the power to cut at the same rate of an equivalent AC 305mm saw, with the ability to cut up to 500 pieces of 78mm pine base board on one 12.0 Ah battery charge

- The HIGH OUTPUT™ system of tools elevates the M18 FUEL™ technologies to a new level and delivers extended performance and extended run time. These tools are designed to maximise the partnership with HIGH OUTPUT™ batteries

- Large sliding fences gives maximum support to the material being cut providing stability and accuracy

- Trenching stop with depth adjustment allows the user to make trenching and rebate cuts

- ONE-KEY™ tool tracking & security offers a free of charge cloud-based tracking network and inventory management platform for your tools. ONE-KEY™ also features a remote locking functionality

- Integrated carry handle allows easy transportation on and off the jobsite

- Steel detent plate with preset angles gives repeatable accurate cuts

- LED light to illuminate the work piece and cut line in low light conditions

- Flexiblebattery system: works with all MILWAUKEE‚® M18™ batteries

![MILWAUKEE M18 FUEL 190 MM MITRE SAW [BARE-TOOL]](https://catalyst-dev2.wylog.com/media/catalog/product/cache/503f2f5e25f27962b01fad949171e229/4/9/4933459634_0_14.jpg?t=20260207)

![MILWAUKEE M18 FUEL ONE-KEY 305 MM MITRE SAW [BARE-TOOL]](https://catalyst-dev2.wylog.com/media/catalog/product/cache/503f2f5e25f27962b01fad949171e229/M/I/MIL4933471205_0_7.jpg?t=20260207)

WhatsApp us!

WhatsApp us!